Our Plastic Injection Molding Diaries

Wiki Article

The Ultimate Guide To Plastic Injection Molding

Table of ContentsThe Only Guide to Plastic Injection MoldingThings about Plastic Injection MoldingHow Plastic Injection Molding can Save You Time, Stress, and Money.Excitement About Plastic Injection Molding

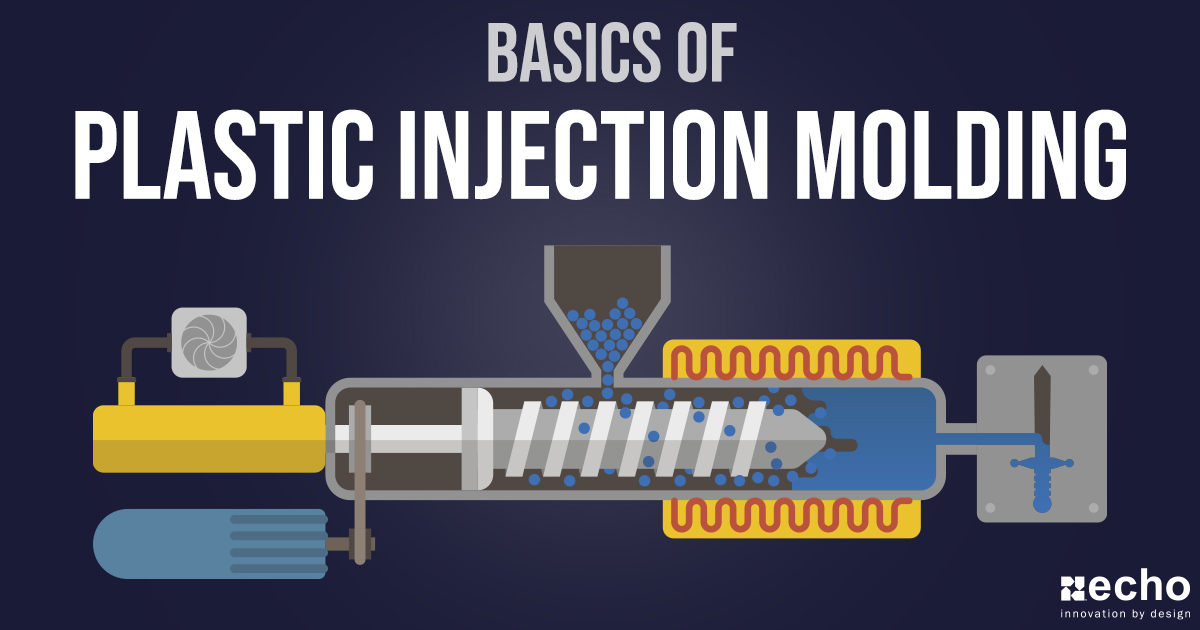

The series of events during the shot mould of a plastic component is called the injection moulding cycle. The cycle begins when the mould shuts, followed by the injection of the polymer right into the mould dental caries. Once the tooth cavity is filled, a holding pressure is preserved to compensate for product contraction.

This triggers the screw to withdraw as the following shot is prepared. Once the component is completely awesome, the mould opens up and also the component is ejected.: 13 Scientific versus conventional moulding [modify] Traditionally, the injection part of the moulding procedure was done at one consistent pressure to fill as well as load the dental caries.

As soon as the cavity is 98% full, the machine changes from speed control to pressure control, where the tooth cavity is "loaded out" at a continuous stress, where adequate speed to get to preferred stress is needed. This allows workers manage part dimensions to within thousandths of an inch or much better. Different kinds of injection moulding processes [modify] Although most injection moulding procedures are covered by the standard procedure summary over, there are a number of essential moulding variations including, but not restricted to: An even more thorough checklist of injection moulding processes may be located below: Refine fixing [ edit] Like all commercial procedures, injection molding can produce mistaken components, even in playthings.

A Biased View of Plastic Injection Molding

Trials are usually performed prior to complete production runs in an effort to forecast defects as well as establish the suitable requirements to make use of in the injection process.: 180 When filling up a brand-new or strange mould for the first time, where shot dimension for that mould is unidentified, a technician/tool setter might perform a trial run prior to a complete manufacturing run. plastic injection molding.Once they accomplish this, they use a small amount of holding stress and also increase holding time up until entrance scorn (solidification time) has actually occurred. Gate freeze off time can be figured out by raising the hold time, and after that weighing the part. plastic injection molding. When the weight of the part does not change, the entrance has frozen as well as no more material is injected into the part.

g. PP combined with ABS, really hazardous if the part is being made use of for a safety critical application as the product has very little toughness when delaminated as the products can not bond. Excess material in slim layer exceeding typical part geometry Mould mores than stuffed or parting line on the tool is harmed, excessive shot speed/material injected, securing pressure too reduced.

The Main Principles Of Plastic Injection Molding

Loading also quickly, not permitting the sides find more info of the component to establish. Likewise mould may be out of enrollment (when the 2 halves do not centre properly and component wall surfaces are not the exact same thickness). The provided information is the usual understanding, Modification: The Absence of pack (not holding) stress (pack pressure is used to load out despite the fact that is the part throughout the holding time).

Simply put, as the part shrinks the material divided from itself as there was not sufficient material in the dental caries. Deep space could take place at any type of area or the component is not limited by the thickness yet by the resin circulation as well as thermal conductivity, but it is most likely to occur at thicker locations like ribs or managers.

Knit line/ Combine line/ Transfer line Discoloured line where 2 circulation fronts meet Mould or worldly temperatures established too reduced (the material is cool when they satisfy, so they don't bond). Time for change between injection as well as transfer (to packaging as well as holding) is prematurely. Twisting Altered part Air look at this site conditioning is too brief, material is as well hot, absence of cooling down around the tool, incorrect water temperature levels browse around this site (the parts bow inwards towards the warm side of the tool) Irregular diminishing in between areas of the component.

Things about Plastic Injection Molding

125 inch wall density is +/- 0. 008 inch (0. 2 mm).: 446 Power needs [edit] The power required for this process of injection moulding relies on several things and varies between products made use of. Production Processes Reference Guide states that the power demands depend upon "a product's details gravity, melting factor, thermal conductivity, component dimension, and also molding rate." Below is a table from page 243 of the same reference as previously discussed that finest shows the attributes pertinent to the power needed for the most generally made use of products.Along with installing evaluation systems on automatic devices, multiple-axis robotics can get rid of components from the mould as well as position them for more procedures. Certain instances include eliminating of components from the mould right away after the parts are created, along with using device vision systems. A robot grasps the component after the ejector pins have been extended to release the part from the mould.

But why is shot molding device manufacturing so reliable? As well as how does it function? To discover, allow's dig right into the subject and address all of the important inquiries, including what it is, the process behind it, its major advantages, and exactly how to choose the appropriate company. What is Injection Molding? is the procedure of utilizing plastic to manufacture a large range of components and things.

The injection molding equipment utilizes custom-made molds to load them out according to specifications, developing identical duplicates that can be tailored in a range of means. What's more, injection molding is a really versatile procedure, permitting a vast array of different materials and also finishes, which makes it a prominent alternative in numerous markets with entirely different goals and also needs.

Report this wiki page